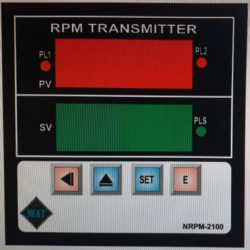

Conductivity Brix Transmitter Model NCBTM-59

Narendra Electronics and Technology here introduces the Brix Transmitter .Our device can efficiently measure the brix The Industries that require to measure the sugar content .It can be used in sugar mills or the food industries that require a sucrose measurement can rely on our product like in candy making ,cookie manufacturing ,beverages production etc . Our Brix Transmitter are working successfully in many sugar factory since last two years.

This product can take the Brix measurement of all PAN, Sulphiter Liquid Sugar etc. User can see the Brix measurements online on his/her mobile device and analyse the data on his/her computer.

(Click here to download product catalog)

Introduction

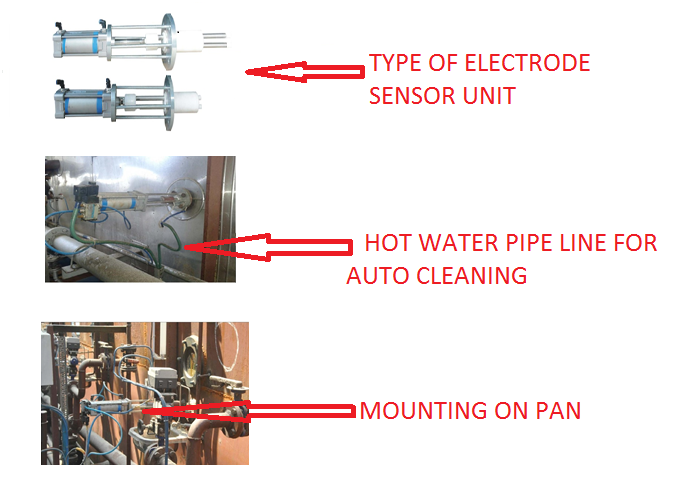

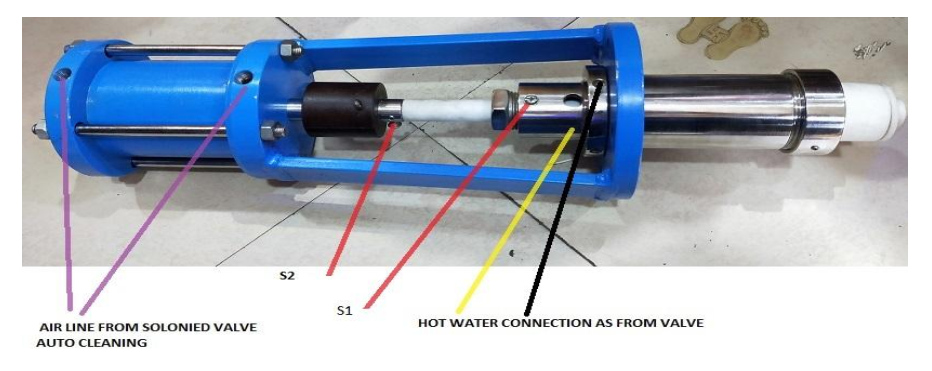

This is Microprocessor Based Online Conductivity Transmitter for Brix Reference Measurement System. The Instrument Measure Conductivity of Brix in Batch/Continuous Vacuum Pans etc., our transmitter has an efficient working in B batch pan B continuous pan and C batch pan and C continuous pan and A Batch pan etc. It Have Two Relay control o/p for electrode Auto Cleaning. In the parameter of auto cleaning user can be set time for auto cleaning interval (As time In minutes, Like 30/60 etc.). During The auto cleaning instrument hold last o/p value up to cleaning process complete. Its fundamental principle is conductivity. It is used to measure messecute’s conductivity. Conductivity is inversely proportional to brix (if conductivity increases then brix decreases and vice – versa). Here the constant is K its value is dependent upon two factor i.e temperature and Conductivity.

BRIX = K *1 /CONDUCTIVITY

The Instrument is Field Programmable and user friendly. The Instrument Have One computer communication Port (Rs485). It also has an Optional feature of WIFI connection Along with one Analog Isolated of 4-20mA.

How to use?

Step1: Switch the power on

Step2: Select The Parameter Temperature and set the value of temperature as that is found near the sensor.Step3: set the value of Action parameter As 0 value.

Step4: Now Select the output parameter , Here The user can decide whether they want output in Brix Or Conductivity. It can be Done in the Following Way:

0 value for conductivity

1 Value for Brix

Step5: Auto Cleaning Mode can be used in two following ways

During This Mode if we measure the liquid Sugar Then Water connection should be disconnected.

Or If we measure Of Brix in Pan there is a need of hot water connection for Sensor.

Note:

Set the value as 10 in the parameter of cyl_in_out

Set the value(minutes) in the parameter of Auto Cleaning time so that after the given time it will auto clean.

Step6: Communication Parameter Can be Selected from Any of the One from Following.

Value 0 for Disable Communication.

Value 1 for Modbus Commination(RS485) ,If this value is set Then we have to set Slave ID Parameter value from 1-255.

Configuration

Press PRG key for 5Seconds Display Parameter Action.

Now user can select Parameter that they want to modify by use Of Up/Dn key, then press Enter Key after That use Up/Dn key to modify further,

and then Press Enter Key to Store. Now Select Next parameter and apply same .

If want Exit from Configuration Mode then select Exit by Use UP/DN key and Press E key Now System in Run Mode.

Caliberation

Press PRG Key for 5 seconds and display Action parameter ,Now use UP/DN Key To select Auto Tune Parameter . After that press and hold PRG key for

1 second now press E key and now leaves both keys, NOW the transmitter will display “Calibration On>>”Wait for up to calibration has to be done. After

calibration complete, it will Show value of Brix.

Applications

Batch Pan Automation.

Continuous Pan Automation.

Molasses Conditioner Automation

Liquid Sugar syrup Brix measurement etc.

Parameters & Descriptions

Action: 0= Forward, 1= Revers Action ( On Display & Output 2k=100% (20mA) & 200E = 0% (4mA) )

Auto Cleaning Time: For Electrode Auto Cleaning Time set (0-60000 Minutes)

Auto Tune: For Auto calibration

Temperature: set the value of temperature Nos.Of In/Out CyL : In this parameter User can be set value of pneumatic cylinder In/Out Numbers(During Auto Cleaning).

Output: Here The user can decide whether they want output in Brix Or Conductivity.(1/0)

Modbus Comm. Id.:

Note: During Auto Cleaning hot water not apply when you are using in syrup brix sensing.

Modbus Comm. Id.: set Slave ID Parameter value from 1-255.

An Optional feature of WIFI connection.

Specifications

Power Supply: 220V AC, @50HZ

Display: Blue LCD/ Backlit LED

Enclosure: ABS plastic 96x194x223 mm (HxWxD )

Overall size: 96x194x223 mm (HxWxD )

Panel cutout: 184X92mm(WxH)

Output: 4-20 mA Isolated (Conductivity/Brix)

Accuracy: 99.8%

Input: S.S Conductivity Electrode

Auto Cleaning Timer: 0- 60000 Minutes.

2Nos Relay: Both Relay use for Auto Cleaning

Relay RL1: For Water on solenoid value

Relay RL2: For cylinder In/out solenoid value

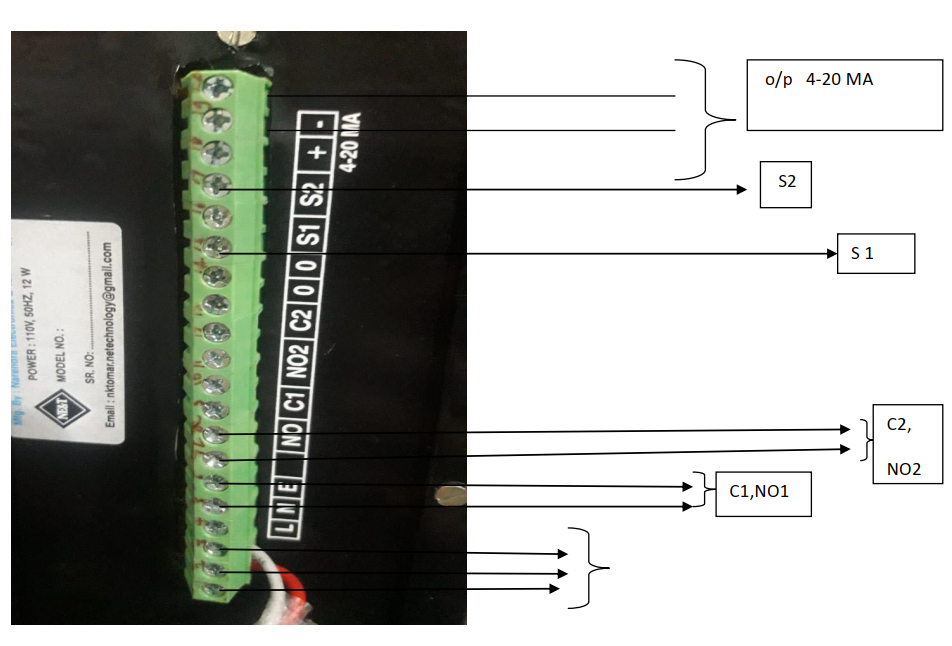

Terminal Details

L: Phase of 220v AC @50Hz

N: Neutral

E: Earth

Sensor Input: S1, S2 from electrode uni

C1, NO1: Water on solenoid value

C2, NO2: In/out solenoid value

+ / – : o/p 4-20 mA(Isolated)